Pipeline Advisor is Ausenco’s digital-twin hub for pipeline operations. Transform live instrumentation, historical and GIS data into a high-fidelity virtual model that keeps your operations inside design limits, spots leak in under a minute and guides your integrity decisions.

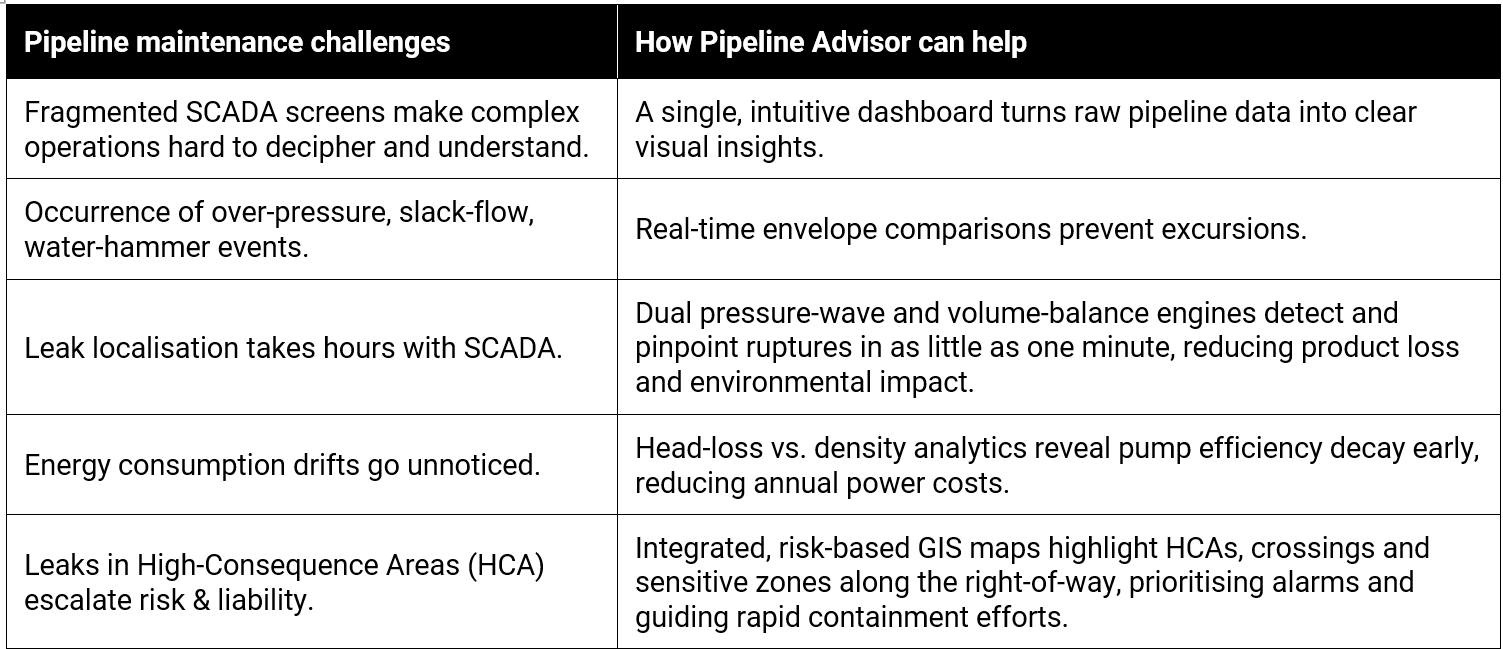

A proven, easy-to-use customisable software solution, it continuously synchronises a physics-based hydraulic model with real-time pressure, flow, density data, as‑built construction records and risk‑based GIS layers. The software turns raw pipeline telemetry and geospatial data into clear, actionable insights, enhancing SCADA systems to support integrity decisions and maintain safe operations within design limits..

Pipeline Advisor allows operators to:

- Validate design envelopes in operation — Automatic alerts are generated when pressure or velocity drifts toward critical limits.

- Simulate stress-test scenarios — Operators can safely run “what-if” simulations using the live model, testing factors such as valve behavior, batch changes, and increased fluid densities, all without affecting actual plant operations.

- Close the integrity loop — Incorporate pipeline inspection data, wall-thickness updates and roughness growth into the digital twin model to continuously refine and improve future predictions.

Key features

- Leak Detection: Quickly detect and prevent leaks with two independent CPM-based systems (pressure waves and volume balance), designed with filters to minimise false alarms and ensure reliable leak identification.

- Operational Monitoring: Keep your pipeline running safely and efficiently with real-time tracking of key operational parameters, including batch interfaces and risk zones, helping operators maintain optimised and safe conditions.

- Simulation: Predict critical conditions and optimise operations with advanced simulations of slurry behaviour, valve configurations, and different fluid batches. Foresee overpressure, rupture disc events, abnormal velocities, and slack flow to support informed decision-making and operational training.

- GIS Integration: Visualise and analyse pipeline construction data, risk zones, and real-time monitoring in one centralised platform. Prioritise high-consequence areas and sensitive zones to support faster, more informed decisions.

- Energy Efficiency: Reduce energy consumption and cut costs by optimising pump and valve operations. Guidance on operational adjustments ensures improved performance while maintaining safe and efficient pipeline management.

Built on robust, client-server architecture, Pipeline AdvisorTM integrates advanced connectivity, redundancy, and secure multi-user access to support the demanding requirements of long-distance pipeline operations. Its subscription-based model enables continuous software improvements while ensuring effective monitoring of fluid transport systems in line with operational, engineering, and integrity standards.

Proven performance

Our software has been proven across diverse mining operations and long‑distance pipelines worldwide, helping to achieve stability and reliability on assets where downtime is not an option.

- 20+ live software deployments on four continents to protect iron ore, copper, nickel, water and tailings pipelines and supporting infrastructure.

- 3,000+ km of pipeline monitored every day through a single code base

- 98%+ platform uptime thanks to redundant collectors and fail‑over servers

- >95% renewal rate, demonstrating sustained client confidence and value

Ready to see your own data in a digital twin? Book a live demo or talk to one of our experts.