Controlling and managing work orders is key for organisations to improve their assets' performance, reduce risks and improve productivity. Work management provides a structured approach to maintenance—integrating planning, scheduling, execution and continuous improvement.

Work management ensures that maintenance activities are executed efficiently, with clear planning, prioritisation and coordination. Tools like Computerized Maintenance Management Systems (CMMS) help shift organisations from reactive to proactive approaches by enabling better scheduling, resource allocation and task tracking.

Performance metrics such as completion rates and mean time to repair support continuous improvement and informed decision-making. When aligned with asset management goals, this structured approach enhances reliability, safety and cost efficiency. Work management also is key to successful shutdowns, enabling better planning and execution. Our team supports this with expert roles, training and on-the-job guidance.

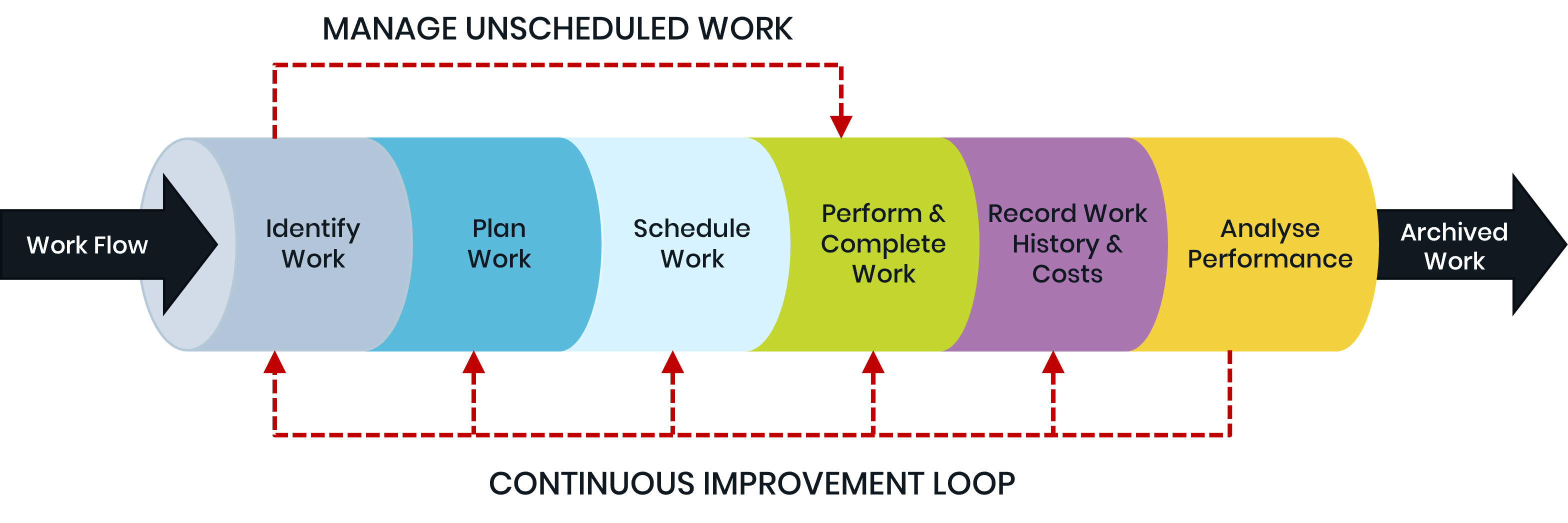

The following diagram illustrates our work management process:

This process includes:

- Work identification and prioritisation: It begins with identifying work through inspections or monitoring, followed by formal requests in the CMMS and prioritisation based on safety, impact, urgency and cost.

- Planning: Defining scope, labour, materials, safety procedures and estimated time.

- Scheduling: Setting timelines aligned with production plans and resource availability.

- Execution and completion: Performing the work, capturing data and finalising documentation for follow-up and history.

- Key performance indicator tracking: Including Mean Time to Repair (MTTR), Mean Time Between Failures (MTBF), work order compliance and backlog aging.

- Analysis and improvement: Analysing trends, improving reliability, and refining processes.

In summary, here are the main advantages of implementing work management:

- Improved reliability and efficiency

- Cost and resource optimisation

- Enhanced safety and regulatory compliance

- Data-driven improvements

- Better communication and coordination through identifying clear roles, setting timelines and improving schedule adherence.